PRODUCT CATEGORIES

May 14, 2025

Thank you for purchasing GForce Performance Engineering Half Shaft Axles! If receiving fully assembled CV half shafts (stubs bolted on), we use paint marks on the CV bolts for quick checks to make sure the bolts have not loosened up at any point. This is a critical mating surface of the axle, and if the bolts loosen up at any point, the CV to stub will lose its clamping force and potentially shear bolts or damage other parts. If receiving partially assembled CV half shafts (stubs not bolted on) ensure a thorough clean of the supplied bolts and the bolt holes on both the half shaft and the supplied stubs. Once fully assembled ensure proper torque is applied following the instructions below. It is strongly recommended that a paint pen be used to apply paint marks to the bolts and CV housing after torque as a visual aid to ensure bolts remain torqued to spec. It is recommended that the cv bolt torque lines be checked periodically. As well as every 15,000-20,000 miles under normal driving conditions. DO NOT REMOVE CV BOLTS FOR INSTALLATION!!! If it is necessary for stub replacement, use new CV bolts and clean both bolt threads and threaded stub holes to remove any existing Loctite, oil, or debris. Apply Red Loctite 263 to bolt threads and in the bolt hole before installation and torque to 75ft/lbs. If threads are not cleaned, you may not achieve the correct torque values or the Loctite may not set up properly to secure the bolt, AND THEY WILL VIBRATE LOOSE!!! **IMPORTANT** Not all GForce axles are not equipped with ABS/Speed sensor rings be sure to swap your factory rings if applicable. Specifically, Mopar requires you to swap the factory ABS rings on all Challenger, Charger, and 300 models. Some vehicles such as the Mopar platforms and 5g Camaro platforms already have aggressive axle angles from the factory, and if lowered, can cause premature CV wear or failure. Always check for clearance on CV’s, CV bolts, Boots, and axle bars upon install. On some vehicles, half shafts might make contact with the control arms at full wheel droop. It is important to never run the car in drive while the rear end is hanging. Some cars might run into boot clearance issues with shocks or aftermarket coilovers . In most applications, the shock body bolts at the top or bottom can be loosened and allow a little movement to help with clearance. S550 Mustang and all Mopar platforms are tight on clearance with factory components. Other vehicles using aftermarket coilovers might need to upgrade to low profile boots to help with additional clearance. MAKE SURE YOU HAVE ADEQUATE CLEARANCE AT RIDE HEIGHT BEFORE DRIVING! We do NOT send out individual components for boot replacement or repair! DO NOT let the axles hang by either inner or outer stub!!! The weight can bend the boot flanges causing sealing issues and ultimately allow enough angle for the CV balls to come out of their races, which can cause serious issues internally. Outer stub nut is 10% less than factory spec (Ex: 240ft/lbs factory spec would be 216ft/lbs). Be sure to use Red 263 Loctite. S550 Mustangs DO NOT follow Ford’s factory spec; Instead, torque them to 200ft/lbs . Stub failures that separate at the threads are due to being over tightened and NOT subject to warranty!!! Must use the supplied retaining ring/ axle nut for installation if applicable. OEM retaining rings and axle nuts will not work and will void your warranty if used. Fitment GForce axle shafts were manufactured based on OEM suspension. Aftermarket shocks, control arms, etc. may present clearance issues. If CV boots have clearance issues, low profile boots can be purchased at an upgraded cost. The low profile boots reduce the amount of available axle angle in comparison to the standard boots, so they are not ideal for lowered or high axle angle vehicles. This includes 2010-15 Camaro and all years of Mopar platforms. If you have questions or would like to add low profile boots to your axles, please contact us for more information. Damage Prevention NO DRIVELINE COMPONENT IS BOMBPROOF! GForce does not put a power rating on any driveline components as there are entirely too many variables that can affect a driveline component outside of power. We take great pride in trying to build the strongest driveline components to fit within certain applications, but it is important to know that You, the end customer, are responsible for seeing to proper installation and You, as the driver, are responsible for the lifespan of your axles or other driveline components. Most of the applications we are working with are very heavy and we are often asking a lot of driveline components, be it OEM or aftermarket. These heavier cars paired with high torque levels make all driveline components more susceptible to failure due to small mistakes, such as wheel hop. Many customers understand that wheel hop, tire shake, tire skipping, tire chatter are all bad things, but there is often a misunderstanding of how destructive it can really be. The heavier the vehicle and more torque the vehicle is making, the more your window of forgiveness begins to narrow. This can result in CV’s loosening prematurely and more severely, splined stubs and axle bars shearing, which is NOT a fault of the axle, so please use your best judgement when driving in any given scenario, be it track or street. It is worth noting that most wheel hop related issues rarely cause an immediate failure, with certain exceptions. The result of repeated cycling torque spikes will often weaken the material of a given component such as an axle bar or stub shaft, then each subsequent hit will continue to weaken the component until it fails completely. If you know that you have driven through a particularly abusing situation, it would be wise to pull the axles and assess the splines of the inner and outer stub shafts as a maintenance procedure. If they have started to twist or shift, then you might be able to prevent a more catastrophic failure. We encourage all end users to read up on the appropriate measures that they can take to help prevent wheel hop with their specific vehicle. This can be anything such as aftermarket bushings, shocks, springs, control arms, tire type, or excessively low tire pressure. Two of the most fundamental pieces we look at to help control rear end movement and prevent wheel hop start with the cradle and differential bushings. Both of these bushing sets are often very soft from the factory, and although the provide smooth ride quality, they allow a considerable amount of movement in a performance scenario, which can lead to a number of concerns. Service All driveline components will fatigue or wear over time depending on how the vehicle is driven and what level of performance is demanded from them. CV’s will loosen up over time, but with our current design, axles can be sent in for service so boots, fasteners, and CV assemblies can be serviced without scrapping the complete axle assembly. It is up to each customer to establish their own maintenance intervals based on the abuse their car sees. Individual inner or outer splined stubs and axle bars can be replaced as well if they are twisted or damaged due to wheel hop or simply from power levels exceeding capability of the material. Customers can reach out to GForce directly for current repair costs or component replacement, as well as return authorizations for service – sales@gforce1320.com We want to see your daily drivers, builds, projects, and race cars!!! Tag us @gforce_1320

By WebAct Web Design

•

March 2, 2023

Damage Prevention NO DRIVELINE COMPONENT IS BOMBPROOF! GForce does not put a power rating on any driveline components as there are entirely too many variables that can affect a driveline component other than just horsepower. We take great pride in building the strongest driveline components to fit certain applications, but it is important to know that YOU, the end customer, are responsible for proper installation and YOU, as the driver, are responsible for the lifespan of your axles or other driveline components. Most of the applications we are working with are heavy vehicles and we are often asking a lot of the driveline components, be it OEM or aftermarket. These heavier cars, paired with high torque levels make all driveline components more susceptible to failure due to small mistakes, such as wheel hop. Many customers understand that wheel hop, tire shake, tire skipping, tire chatter are all bad things but there is often a misunderstanding of how destructive it can really be. The heavier the vehicle and more torque the vehicle is making, the more your window of forgiveness begins to narrow. This can result in CV’s loosening prematurely and more severely, splined stubs and axle bars twisting or shearing, which is NOT a fault of the axle. So please use your best judgement when driving in any given scenario, be it on the track or the street. It is worth noting that most wheel hop related issues rarely cause an immediate failure, with certain exceptions. The result of repeated cycling torque spikes will often weaken the material of a given component such as an axle bar or stub shaft. Then each subsequent hit will continue to weaken the component until it fails completely. If you know that you have driven through a particularly abusing situation, it would be wise to pull the axles and assess the splines of the inner and outer stub shafts as a maintenance procedure. If they have started to twist or shift, then you might be able to prevent a more catastrophic failure. We encourage all end users to read up on the appropriate measures that they can take to help prevent wheel hop with their specific vehicle. This can be anything such as aftermarket bushings, shocks, springs, control arms, tire type, or excessively low tire pressure. Two of the most fundamental pieces we look at to help control rear end movement and prevent wheel hop start with the cradle and differential bushings. Both of these bushing sets are often very soft from the factory and although they provide smooth ride quality, they allow a considerable amount of movement in a performance scenario. Which can lead to a number of concerns or issues. Service All driveline components will fatigue or wear over time depending on how the vehicle is driven and what level of performance is demanded from them. CV joints are a wear item and will see wear over time, but with our current design, axles can be sent in for service. So boots, fasteners, and CV assemblies can be serviced without scrapping the complete axle assembly. It is up to each customer to establish their own maintenance intervals based upon the manner in which their car is driven. Individual inner or outer splined stubs and axle bars can be replaced as well if they twist or are damaged due to wheel hop or simply from power levels exceeding capability of the material. Customers can reach out to GForce directly for current repair costs or component replacement as well as return authorizations for service – sales@gforce1320.com Contact Us

By WebAct Web Design

•

November 10, 2021

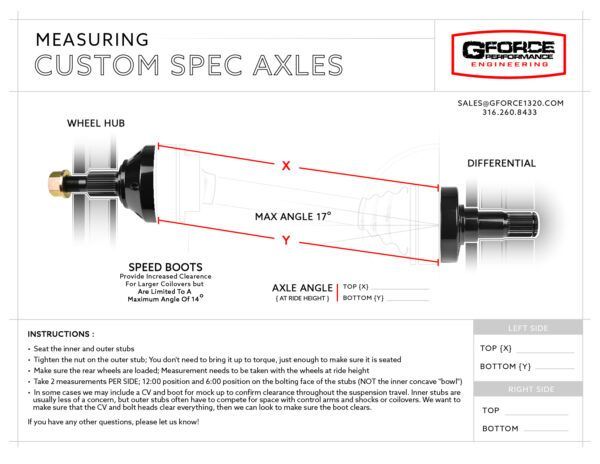

The diagram below illustrates the proper anchor points when measuring for custom axle shafts. Note the inner and outer stub shafts are installed in the car. Ensure that the stub are seated properly and secure before measuring. Ideally, measurements should be taken at ride height; not at fill droop or compression.

By WebAct Web Design

•

November 10, 2021

Renegade vs Outlaw The GForce Renegade Axles are the tried and true axle design that has become the standard in performance half-shafts. The Renegade axle has waivered very little from its roots some 15 years ago. Advancements in materials, heat-treat processes and machining have only improved their efficiency and capabilities. It is hard to argue with the Renegade’s pedigree for strength and overall value.

By WebAct Web Design

•

September 8, 2016

If you ever had any questions about what it takes to do an axle upgrade on your car, here is a great video walking you through the steps. The guys at CJ Pony Parts take a set of Ford Performance axles made by GForce Engineering and do a quick step by step install on a new S550 Mustang.

By WebAct Web Design

•

August 15, 2016

Knowing what wheel hop is and what causes it is the first step to understanding anti-wheel hop technology and the advantages it provides. “Anti-wheel hop” is actually a technology developed by General Motors years ago on some of the first rear-wheel drive IRS cars. The concept is simple, use a larger diameter axle bar on the side that is most likely to receive the most power first. Here is why it works. Wheel hop occurs due to a variety of reasons. Suspension, driveline, tires, power levels, etc. all play a part in wheel hop. But, at the most fundamental level, wheel hop occurs when the axle is “wound up” (twist). When the force of the axle trying to unwind exceeds the grip of the tire, it breaks loose and snaps back. Within an instant, the tire tries to grab and the axle winds up again and the process starts over again. This constant wind and unwind casuses the tire to bounce and is what we call wheel hop. There are a variety of fixes for wheel hop. Stiffer suspension, different tires, etc all help to “stick” the tire. Another fix to help eliminate wheel hop is better axles. All GForce Engineering axles feature the Anti-Wheel Hop Technology. Larger diameter axles, premium materials and more strength and rigidity all reduce wheel hop. This combined with the appropriately matched suspension can virtually eliminate wheel hop and ensure your car hooks like you want it to. Its important to note that ALL GForce axle feature this same Anti-Wheel Hop Technology. This includes our 850HP axles, Outlaw axles and 9″ axles.

By WebAct Web Design

•

August 8, 2016

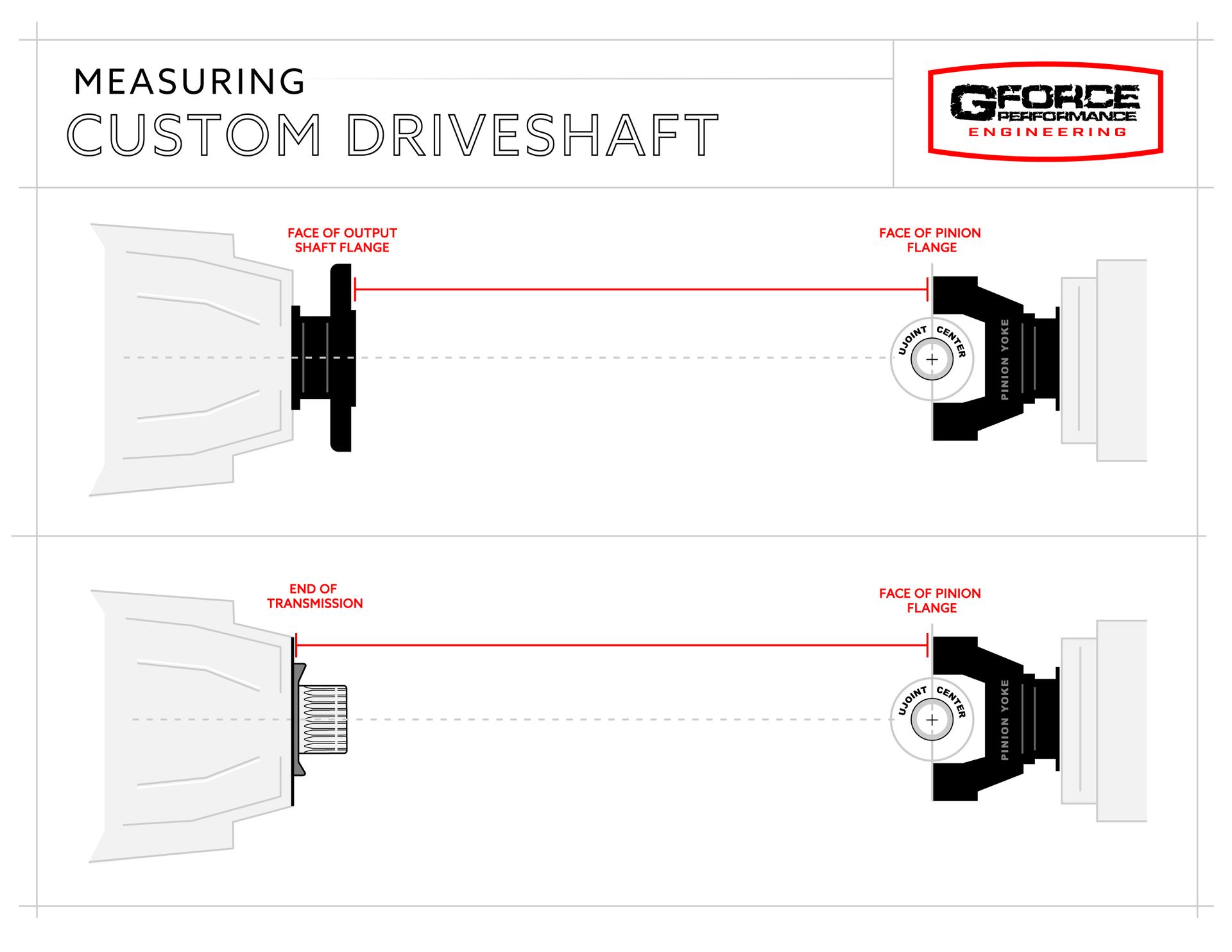

Proper measurements for your custom driveshaft. Whether you are ordering a custom driveshaft for your project or double checking your’s cars measurement when ordering a GForce driveshaft, proper measurement is critical to ensure you receive the ideal driveshaft length for your application and the lowest risk problems down the line. Measuring, in most cases is extremely simple. Below are a couple quick tips and diagrams to help make sure your measurements are as accurate as possible. Slip Yoke: If you are looking for a driveshaft with a transmission slip-yoke, make sure to indicate what transmission you have. Measurement is taken from trans seal on the tailshaft of the transmission to either the face of the diff yoke (which is u-joint centerline) or the face of the diff flange (if your differential is so equipped). Measurement “X” on the diagram shown below. Note: If you have a GM 4L80 transmission, we will need to know if your transmission output shaft is threaded or non-threaded. This can be determined by looking at the inside of the center hole on the back on the output shaft. Some are threaded and others or not. This will determine which slip-yoke we include with your shaft. Transmission Flange: Most GForce Engineering driveshafts listed on our website are direct replacement upgrades for OE driveshafts. In many late model cars, both the transmission and differential use output flanges instead of a slip yoke on the trans and open u-joint on the diff yoke. In this case, measurements is simply taken from inner face of the flange to inner face of the flange. GForce 9″ Kits: Measuring for a GForce 9″ Kits driveshaft can be a combination of the above two scenarios. Depending on whether your transmission requires a slip yoke or is equipped with an output flange. Measurement is taken from one of these locations to the face of the yoke on the diff. The face of the yoke is also referred to as u-joint centerline, in this case. U-Joints: If ordering a custom driveshaft, its is important to know what u-joint you need for your differential. All GForce 9″ Kist require the common 1350 U-Joint. Other commonly used sizes are 1330 and 1310.